|

OPW 61SO型卸油防溢阀

OPW 61SO Overfill Prevention Valves

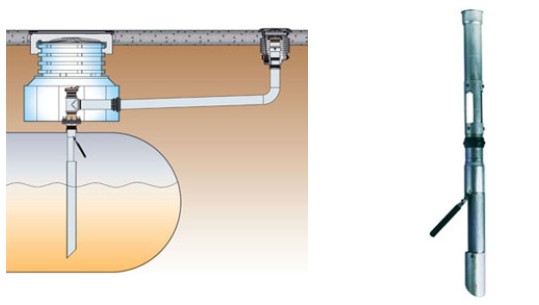

OPW 61SO型是一种两级封闭的防溢阀,主动切断油品的输入以防止油品溢出油罐,防止污染环境和产生危险。61SO型设计仅用在密闭重力卸油,它能安装在新的和现有地下油罐的立管上,61SO安装简单,不需破坏混凝土,不需特殊的人孔。61SO型具备多种型号以适用任何地下油罐,包括:两点式,同轴式,提动同轴式,远端卸油式。

OPW61SO型是两级封闭的防溢阀。当油品升至油罐容量的大约95%时,防溢阀的机械装置释放,自动关闭卸油。此时通过一个分流管减少流速至大约5GPM。操作员然后可以停止卸油,切断以及排空卸油软管。每次当油品超过油罐容量的95%时,卸油阀们就会自动关闭。如果没有停止卸油而且油品超过油罐容量的98%时,分流阀将完全关闭。直到油面降至复位点下,不会有油品流进油罐中。

OPW 61SO Overfill Prevention Valve

OPW 61SO不同型号可满足各种地下油罐的应用,包括:两点式,同轴式,提动轴式,远端卸油式。61SO和卸油管道可以用螺纹或法兰连接,以保证卸油防溢阀安装在和适的位置,安全关闭卸油管。

OPW 61SO型卸油防溢阀特点:

简单,容易和快速安装:无需发掘和特殊的人孔。

经济节约:花费为其他昂贵、复杂和难于安装的阀门的一小部分。

装备完善: 提供全新的上部和下部竖直管道,安装工具和完整的手册,便于减少现场工作时间。

完全自动操作:无需预先检查操作,无需复位,不会中断或者滥用。

不会对油罐产生压力,直接由油品液面控制。可以使用量油尺测量油品液面

直接迅速改进:适用于配有3”/4”卸油立管的新旧油罐。

快速排空的特点,当顶部压力释放时,自动排空油喉。

工业界最佳流速。

OPW 61SO防溢卸油阀的优点:

和溢出警告系统的比较完善的自动控制:不需依赖卸油工警戒性和反应速度来保证防溢。

按照EPA要求保持地下油罐顶端干燥:消除由松动的油喉配件而引起的渗漏和对双层排空管的要求。

不许依靠地下油罐内的压力来停止卸油:减少卸油时间和浅洒的危险。

卸油快速:油品可顺利进入油罐,直到液面达到关闭位置时油喉启动关闭功能。

简单的和低价安装:不论两点式和同轴式卸油装置,不需额外的挖掘、人空和排空管的改造。

OPW 61SO型卸油防溢阀材料:

阀门主体:浇铸铝

密封条:氟橡胶

浮子:腈橡胶,网格泡沫

上部下部卸油管道:铝

阀门:铝

塑料部分:乙缩醛

螺丝及工具:不锈钢

重要提示:

为了防止油品从地下油箱中溢出,适当地维修卸油置和保证快速接头的联结是必要的。卸油员工应该经过管理和培训,检查卸油弯管和软管的损坏和零件遗失。他们应该经常确定快速接头和软管之间的正确连接。如果卸油装置没有适当的维护或者弯管没有紧密连接到快速接头,当OPW61SO型关闭时会发生严重的溢出,并引起一个危险和环境的问题

注:OPW61SO型只能用在重力下落式卸油器件中,不能用在压力填塞卸油器件中。

61SOM-412C-EVR*? CARB 4", two-point,

ethanol/methanol 120 3.1 not included 2333/8 5.9 1131/2 2.9 120 3.1 126 3.2 25 11

61SOC-4001 Coaxial 60 1.5 83 2.1 1543/8 3.9 531/2 1.4 96 2.4 107 2.7 16 7

61SOC-4011 Coaxial 120 3.1 102 2.6 2333/8 5.9 1131/2 2.9 120 3.1 126 3.2 25 11

61SOP-4002 CARB, pop. coaxial 60 1.5 83 2.1 1543/8 3.9 531/2 1.4 96 2.4 107 2.7 20 9

61SOP-4012 CARB, pop. coaxial 108 2.7 102 2.6 2213/8 5.6 1011/2 2.6 120 3.1 126 3.2 27 12

61SOCM-4000*? Coaxial, ethanol/methanol 60 3.1 not included 2333/8 5.9 1131/2 2.9 120 3.1 126 3.2 25 11

61SO-4BYT Overfill valve only, no drop tubes supplied

61SOR-4000** Remote 72 1.8 83 2.1 1663/8 4.2 651/2 1.7 96 2.4 107 2.7 19 9

61SORM-4000***? Remote, ethanol/methanol 72 1.8 not included 1853/8 4.7 651/2 1.7 120 3.1 126 3.2 19 9

61JSK-4RMT Jack Screw Kit for Remote application

*For use with M85 & M100 methanol fuels **Remote fill applications

61SO Series Overfill Prevention Valves Ordering Specifications

| Product/Suffix Number |

Description |

A-Upper Tube Length |

B-Lower Tube Length |

C-Overall Length. |

Max. Riser Length |

Max. Nominal Tank Dia. |

Max. Actual Tank Dia. |

Weight |

| in. |

m |

in. |

m |

in. |

m |

in. |

m |

in. |

m |

in. |

m |

lbs. |

kg |

| 61SOM-412C-EVR*? |

CARB 4", two-point, ethanol/methanol |

120 |

3.1 |

not included |

233-3/8 |

5.9 |

113-1/2 |

2.9 |

120 |

3.1 |

126 |

3.2 |

25 |

11 |

| 61SOC-4001 |

Coaxial |

60 |

1.5 |

not included |

|

154-3/8 |

3.9 |

53-1/2 |

1.4 |

96 |

2.4 |

107 |

2.7 |

16 |

7 |

| 61SOC-4011 |

Coaxial |

120 |

3.1 |

102 |

2.6 |

233-3/8 |

5.9 |

113-1/2 |

2.9 |

120 |

3.1 |

126 |

3.2 |

25 |

11 |

| 61SOP-4002 |

CARB, pop. coaxial |

60 |

1.5 |

not included |

|

154-3/8 |

3.9 |

53-1/2 |

1.4 |

96 |

2.4 |

107 |

2.7 |

20 |

9 |

| 61SOP-4012 |

CARB, pop. coaxial |

108 |

207 |

102 |

2.6 |

221-3/8 |

5.9 |

101-1/2 |

2.6 |

120 |

3.1 |

126 |

3.2 |

27 |

12 |

| 61SOCM-4000* |

Coaxial, ethanol/methanol |

60 |

3.1 |

not included |

233-3/8 |

5.9 |

113-1/2 |

2.9 |

120 |

3.1 |

126 |

3.2 |

25 |

11 |

| 61SO-4BYT |

Overfill valve only, no drop tubes supplied |

| 61SOR-4000** |

Remote |

72 |

1.8 |

not included |

|

166-3/8 |

4.2 |

65-1/2 |

1.7 |

96 |

2.4 |

107 |

2.7 |

19 |

9 |

| 61SORM-4000*** |

Remote, ethanol/methanol |

72 |

1.8 |

not included |

|

185-3/8 |

4.7 |

65-1/2 |

1.7 |

120 |

3.1 |

126 |

3.2 |

19 |

9 |

| 61JSK-4RMT |

Jack Screw Kit for Remote application |

*For use with M85 & M100 methanol fuels. **Remote fill applications. ***Remote fill, methanol.

Methanol (M85) and Ethanol (E85) models do not include lower drop tube. Adaptor for 3" A.O. Smith Fiberglass Pipe (Drop Tube) is included. Appropriate length of 3" A.O. Smith Fiberglass Pipe is required for lower Drop Tube (not furnished).

61SO Overfill Prevention Valves

The OPW 61SO Overfill Prevention Valve is designed to prevent the overfill of underground storage tanks by providing a positive shut-off of product delivery. The shut-off valve is an integral part of the drop tube used for gravity filling. The OPW 61SO allows easy installation (without breaking concrete) and requires no special manholes.

The OPW 61SO is a two-stage shut-off valve. When the liquid level rises to about 95% of tank capacity, the valve mechanism is released, closing automatically with the flow. This reduces the flow rate to approximately 5 gpm through a bypass valve. The operator may then stop the filling process and disconnect and drain the delivery hose. As long as the liquid exceeds the 95% level, the valve will close automatically each time delivery is attempted.

If the delivery is not stopped and the liquid rises to about 98% of tank capacity, the bypass valve closes completely. No additional liquid can flow into the tank until the level drops below a reset point.

The 61SO Overfill Prevention Valve can be adjusted to shutoff at any desired tank capacity. Please contact the Authority Having Jurisdiction (AHJ) and review local, state, and national codes to determine the regulatory requirements governing shut-off capacity in your region, as well as take into account other considerations such as extreme tank tilt. In all cases, the upper tube must protrude into the tank at least 6-1/2" to ensure that the valve can shut off flow into the tank completely before the top of the tank is wetted as per EPA requirements.

Models of the 61SO are available to meet virtually any UST application including two-point, coaxial, poppeted coaxial and remote fill. Methanol approved models are also available.

OPW 61SO SellSheet 2018

61SO

61SO

Models

Features & Benefits

Ordering Specifications

Replacement Parts

Downloads

Model Descriptions

61SOR Remote-Fill

The OPW 61SOR is designed for two-point remote-fill applications, where the fill point is not directly over the UST. The valve is installed in the tank through a riser pipe directly over the tank. A window in the drop tube is aligned with the entrance of the fill pipe from the remote-fill location to allow product to flow into the drop tube and down through the valve. A riser seal prevents product from flowing into the tank from outside the drop tube. A “trap door” assembly installed in the riser above the tank provides access for a gauging stick. Trap door, adaptor and cap are included with 61SOR.

61SOR Remote Fill Tube Instruction Sheet Order Number: H11964M

61SOC Coaxial

The OPW 61SOC is used for coaxial fill applications, tanks equipped with a single product/vapor return connection. The 61SOC replaces the standard coaxial fill drop tube in a 4" riser fill pipe.

61SO-4000 Series Instruction Sheet Order Number: H11764M

61SOC Coaxial Fill Tube Instruction Sheet Order Number: C03634PA

71SO Vapor-Tight Remote Fill

The OPW Vapor-Tight Remote Fill is designed for two-point vapor-tight remote-fill applications, where the fill point is not directly over the UST. A CARB approved vapor-tight 61SO overfill valve is installed in the sump through a riser pipe directly over the tank. The 61JSK-4RMT Kit installed within a 4” Tee provides an anchoring mechanism by locking the 61SO overfill valve in the tank fill riser. The “trap-door” assembly installed in the riser above the tank retains access for a gauge stick. The 61JSK-4RMT Kit coupled with any Vapor-Tight 61SO Overfill Valve will work for this application.

OPW Overfill Prevention Valves are designed to prevent the overfill of USTs by providing a positive shut-off of product delivery.

OVERFILL PREVENTION VALVES

61SO Overfill Prevention Valves

53VML (30MV) Ball Float Vent Valves

OPW 89 Extractor Wrench

61T Drop Tube

61TC Coaxial Fill Drop Tubes

71SO Overfill Prevention Valve

71SO-T Testable Overfill Prevention Valve

71SOM Vapor Tight Overfill Prevention Valve for Alcohol

61T-SS Drop Tube E85 EVR Approved

|