|

|

|

|

OPW工程系统公司生产的旋转接头广泛应用于化工、石油、石化、炼油、采矿、蒸馏、酿造、油墨、涂料工业,以及农业灌溉和施肥。设计、工厂和维护工程师会在软管管道、灌装臂、软管盘、下水道疏通设备和污水处理设备以及各种工艺机械中使用OPW旋转接头。他们也会在机床冷却液输送、桶料灌装以及各种近距离液体和干散货输送用途中使用。 多功能性是OPW工程系统公司旋转接头的关键,这使在负压或真空条件下使用刚性金属管进行液体和干散货装卸成为可能,并解除了繁重操作和笨重软管所带来的困境或危险。

OPW公司的设计工作在先进的CAD系统支持下,可以更快、更准确满足客户的技术要求。OPW旋转接头经久耐用、质量可靠、便于操作和维护。可选择的材质包括不锈钢、铸钢、结构钢、球墨铸铁、铝和铜,可以满足客户-严苛的规格需求。专业规格有分体法兰型、夹套型、内衬型和镀膜型。

OPW swivel joints中文技术资料PDF下载

60多年来,OPW工程系统公司为一些-具挑战性的液体处理应用提供了创新性的解决方案。我们引以为傲的是可以为您提供定制设计和制造的旋转接头,以满足您的专业需求。工程师们会与您一起工作,满足您使用需求的。

OPW Swivel Joints Catalog

OPW 3000系列旋转接头

- 传统单层压力O型密封圈

- 重负载情况下,双轨滚珠保证内部结构不会偏移

- 多种规格可供选择

- 在更恶劣环境可选用8000系列 多种材质、尺寸和类型:

- 标准尺寸:1” - 12”

- 标准材质:铝制、铜质、碳钢、铸铁、不锈钢

- 标准密封圈材质:Fluorocarbon, PTFE, EPDM, Neoprene

- 接口类型:FNPT, 150/300 ANSI 法兰, Butt/Socket Weld

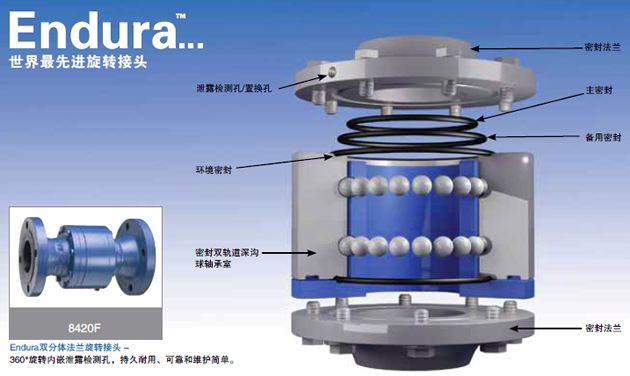

OPW 8000系列 DSF 双分体法兰旋转接头

OPW 8000 Series Endura Split Flange Swivels

Endura 8000系列双体法兰旋转接头

- 好的旋转接头技术

- 专为化工/工业灌装臂应用设计

- 可提供2"、3" 和4"口径规格和多种材质包括碳钢、全不锈钢等

- 500磅压力等级

装卸臂使用旋转接头

更耐用

冗余密封保护

维护更容易

无需拆卸滚珠即可更换密封圈

可更换的轴承系统

泄漏监测

2”、3” 、4”

不锈钢、碳钢和铝合金可选

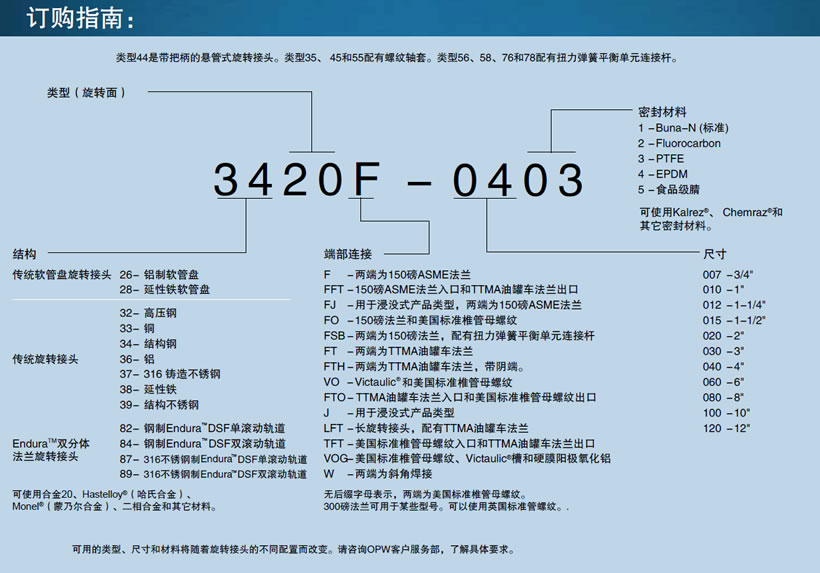

- OPW旋转接头 行业完整旋转接头系列指南

- OPW旋转接头订购指南

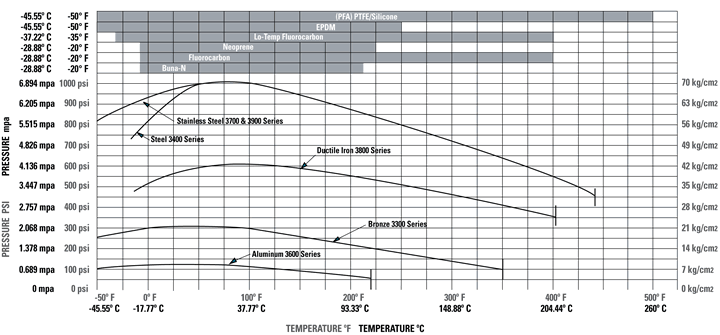

Metal Options

- Aluminum (ASTM B26, A356 T6)

- Bronze ( ASTM B62-83600)

- Carbon Steel (ASTM A105)

- Ductile Iron (ASTM A-536)

- Stainless Steel (ASTM A351-CF3M/CF8M)

Seal Options

- Buna

- Fluorocarbon

- PTFE

- EPDM

- Neoprene

- Kalrez

Lubrication

Lubrication plays an important role in the life expectancy of a swivel joint. OPW has done extensive research to determine the best lubricants for our products. Our standard is a High Performance Synthetic Lubricant (OPW part # 880-0089).

- Specially formulated to reduce friction & wear.

- Requires only annual lubrication

- Will not drip, melt or carbonize

- Complies with FDA regulation 21CFR178.3570

- Temperature Range -40F – 750F (-40C – 399C)

- Not for use with EPT/EPDM Seals. EPT/EPDM seals require the use of OPW 885-0085 lubricant.

Specifications

- 3200 Series (Cast Steel, High-Pressure) Bodies and tails of cast 1040 carbon steel with hardened raceways. Ball bearings are precision-ground steel. Buna-N main O-ring seal with Teflon? back-up ring, and Buna-N O-ring dust seal are standard.

- 3300 Series (Cast Bronze) Bodies and tails of hard, wear-resistant cast bronze (ASTM B62-83600). Precision-ground steel balls, Buna-N O-ring main seal and felt dust seal are standard. 1" size has Buna-N O-ring dust seal.

- 3400 Series (Fabricated Steel) Bodies and tails of 1040 carbon steel with hardened raceways. Welded construction; 100% penetration welding by welders certified to ASME Boiler and Pressure Vessel Code, Section IX. Precision-ground steel balls, Buna-N O-ring main seal, Buna-N O-ring dust seal. Standard flanges are ASME 150 lb. raised face type.

- 3600 Series (Cast Aluminum) Bodies and tails of cast A-356 high-tensile strength aluminum. Precision-ground steel balls, Buna-N O-ring main seal, and felt dust seal are standard. 1" size has Buna-N O-ring dust seal. Flanges are dimensionally compatible to ASME 150 lb. flat face configuration.

- 3700 Series (Cast Stainless Steel) Bodies and tails of high quality cast ASTM A351-CF3M/CF8M stainless steel. Precision-ground stainless steel balls, Buna-N O-ring main seal and Buna-N O-ring dust seal.

- 3800 Series (Cast Ductile Iron) Bodies and tails of cast A-536 ductile iron. Precision-ground steel balls, Buna-N O-ring main seal, and felt dust seal are standard. Buna-N O-ring dust seal standard in 1" size. ASME B16.1, Class 125 dimensionally equal to 150lb. ASME RF Flange.

- 3900 Series (Fabricated Stainless Steel) Bodies and tails of high-quality ASTM A351-CF3M/CF8M stainless steel. Welded construction; 100% penetration welding by welders certified to ASME Boiler and Pressure Vessel Code, Section IX. Precision-ground stainless steel ball bearings, Buna-N O-ring main seal, Buna-N O-ring dust seal. Standard flanges are ASME 150 lb. raised face type.

|